How do ESR Light control product quality?

Quality assurance

Quality is never an accident. It is always the result of intelligent effort. Below six steps shows our process of quality management.

Supplier assessment

ESR Light only work with suppliers with good reputation and reliable quality. First step to build a rock-sold product.

Raw materials inspection

Also called pre-production inspection. Product materials require check for quality as they come in from vendors.

In-process inspection

Also called During Production Inspection. Goods are 100% inspected in production line. The idea is to monitor and find quality issues before they occur and avoid reworking.

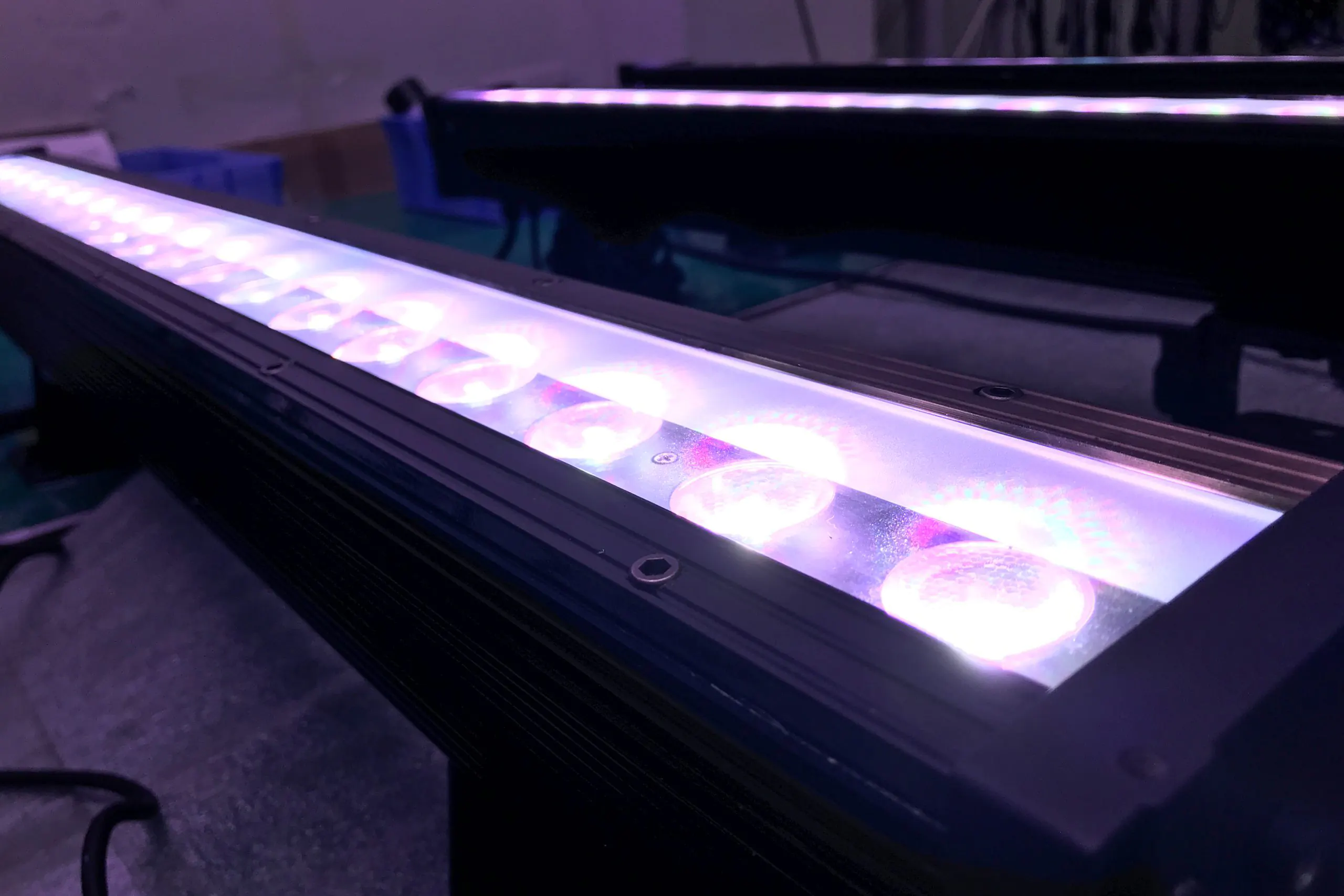

Aging testing

All ESR Light products will be 100% tested for at least 8 hours before packing.

Final inspection

QC conducts measurements of the finished products to ensure they were produced according to specifications.

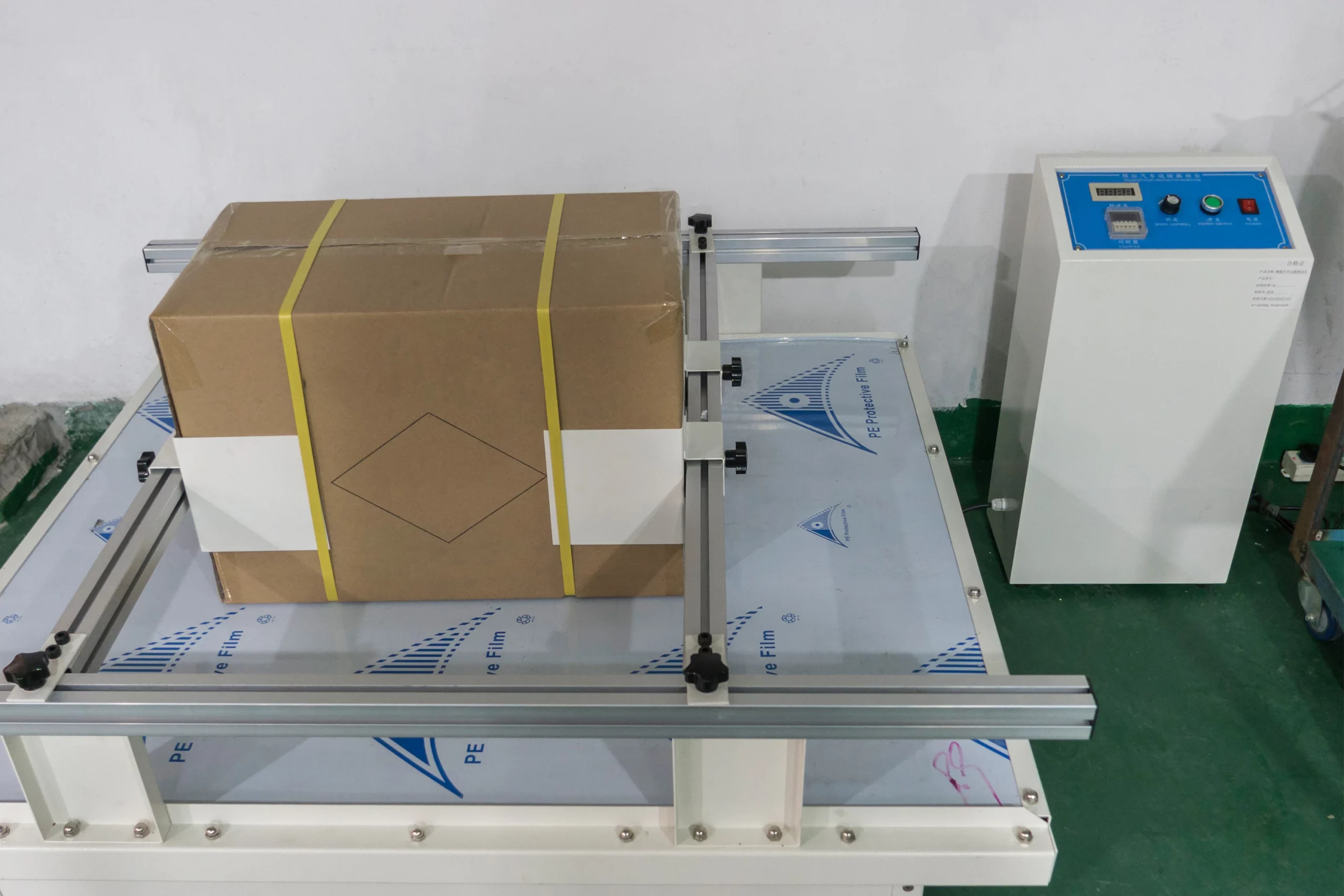

Shipment testing

We will pick several items to do vibration test to simulate the real transportation environment.